What happens in the product development at BAVARIA YACHTS?

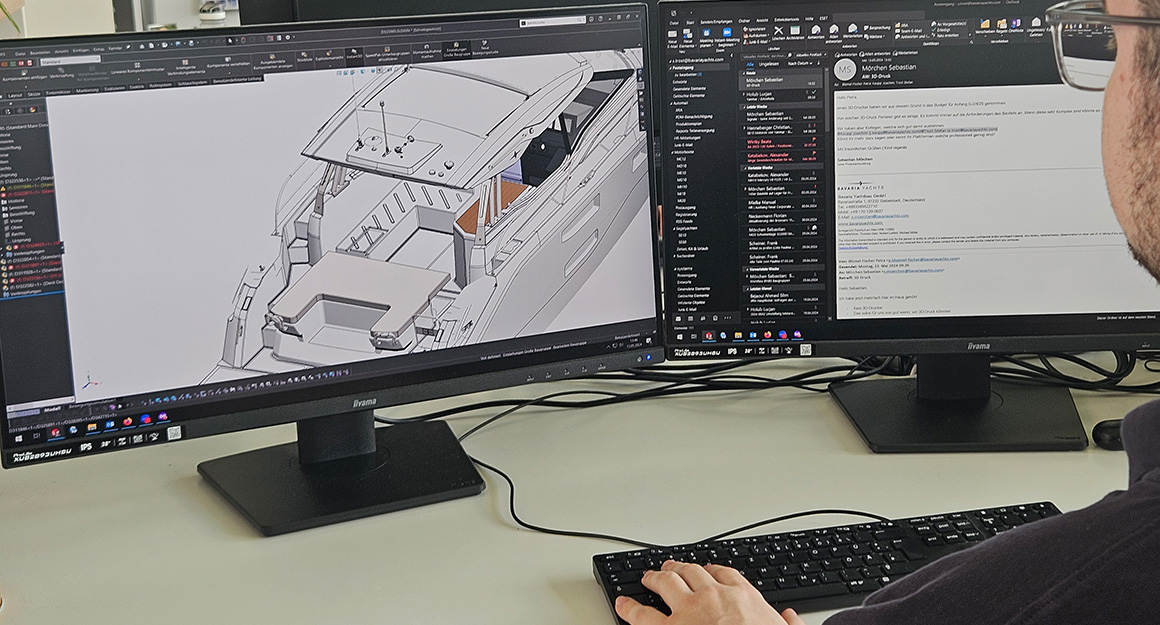

The modern office opposite the cafeteria catches our attention today. Upon entering, there is a bustling silence - typing and clicking. On some screens, we catch a glimpse of complex 3D models and technical drawings. But what exactly are the tasks in product development and what is the department responsible for? Head of department Sebastian Mörchen answers these questions and more in this interview!

Hi Sebastian! What exactly is Product Development responsible for?

Generally speaking, we are mainly responsible for ensuring that the wishes and requirements from product management can be realised. For example, when we want to launch a new boat on the market. We start by drawing up a kind of specification sheet, which contains all the functional and technical requirements. During product development, we then implement the desired functions and elements in accordance with the technical and legal framework conditions.

Product development takes place entirely in the CAD system. From individual parts and assemblies to the complete yacht. We accompany the new boat from the first drawing through the construction of the first prototype to the assembly line and series production. During this process, we always check whether any adjustments need to be made in order to guarantee all functions and an efficient construction process.

If a motor or sailing boat is then produced in series, there is of course still a need for optimisation. Small adjustments are always made at the change of model year or the dimensions of furnishings change, which then have to be mapped in the construction plan. We always have to be involved in this, as we can display all 3D elements in our CAD programme and then derive so-called ‘parts lists’ from them. These are then needed by the purchasing and logistics departments so that they can plan and order enough and the right parts.

Do your orders only come from product management or also from production?

For new products, always from product management and in series production usually directly from colleagues on the production line. That's where you realise the earliest if something could work even better. It can also happen that parts are missing and we have to develop alternatives, which often requires a good solution quickly. This must then also be included in the parts lists.

Which other departments do you work with?

Almost all of them, actually. Starting, of course, with Product Management as an input provider for new projects. Purchasing then deals with parts lists and parts. But project management is also important for us because all new projects are planned there and we are in close dialogue. We liaise directly with our colleagues from Industrial Engineering in Production. They take care of how everything is installed so that a finished product is created.

Not forgetting, of course, the quality and certification department. This is where we check that everything is qualitatively and legally in order.

How long does it take from the sketch to the first prototype?

On average, the development of a new boat takes a year. Then we have the first prototype. However, it still takes a few weeks before a boat runs smoothly on the production line, as some of the work processes have to be reorganised or changed.

What was or is the most exciting project?

Actually, it's always the latest project that we find most interesting. Of course, the latest parts are used and it is always a challenge to design a new boat. Especially when you are nominated for prizes and also win, as with our latest sailingyacht the BAVARIA C46, it is an additional recognition for the work of the employees in product development.

Are you divided into different departments - sailing or motorboat?

On the one hand, we are divided into different areas - the interior, where all the furniture and wooden parts are planned and designed. And Exterior - that's where we design the hull, deck, all the other GRP parts and the sails.

Then according to systems, such as electrical systems and systems such as water, gas and sewage. In some cases, however, we also look after the series boats and new developments.

What does a typical working day look like?

We don't really have one. When developing a new boat, you work your way through the boat step by step, from the foredeck to the saloon to the aft cabins. In series production support, new parts may have to be planned in. It really varies a lot depending on the employee and the day. I think that's what makes it interesting!

Which programmes do you work with?

The main work is done in our CAD programme ‘Solidworks’. The entire assemblies are created there. We can also use it to carry out strength calculations or derive parts lists, which are then transferred to our ERP system. Otherwise, we use the typical Office applications - especially Excel.

What projects are you currently working on?

We are currently working on the model year changes. We are implementing new features here, such as a drinking water treatment plant or other systems. But I can't reveal anything about our new projects at this point!

Too bad, no insider news again! Thanks anyway, Sebastian, for taking the time for us!

Did you like the article? We look forward to your feedback, suggestions or requests at marketing@bavariayachts.com