The motorboat from BAVARIA YACHTS

Experience the pure joy of yachting with a motorboat from BAVARIAPowerful, dynamic, safe, easy to handle and seaworthy - BAVARIA YACHTS motor yachts have many qualities. From bow to stern, they embody the masterful combination of many clever solutions. Decades of experience, extensive know-how and German engineering skills guarantee precision, quality and comfort. With excellent materials, excellent equipment and excellent craftsmanship, our shipyard creates what every BAVARIA stands for: the joy of yachting.

Experience the pure joy of yachting.

The fascination of yachting

Enabling you to enjoy wonderful moments on the water is what drives us every day. Motorboats and yachts stand for tangible power, perfect handling characteristics and dynamism. These characteristics are at the centre of the design and construction of our exclusive boats. We spare no effort and regularly put everything to the test so that you can enjoy a safe and sporty day on the water.

Comfort and individuality for every motorboat enthusiast

BAVARIA YACHTS is one of the most modern manufacturers of motorboats and motor yachts in the world. At our shipyard in Giebelstadt, Franconia, we build exclusive yachts for the discerning customer. Around 700 employees produce over 600 sailing and motor yachts per year. Our portfolio leaves nothing to be desired: The motor yacht series R-LINE (lengths from 12.65 m to 17.95 m), SR-LINE (lengths from 10.87 m - 11.86 m), S-LINE (lengths from 8.76 m to 13.83 m), VIRTESS LINE (12.39 m long) and VIDA LINE (9.93 m long) offer the right type with individual configuration options for every motorboat enthusiast.

Our motorboats: economical and powerful

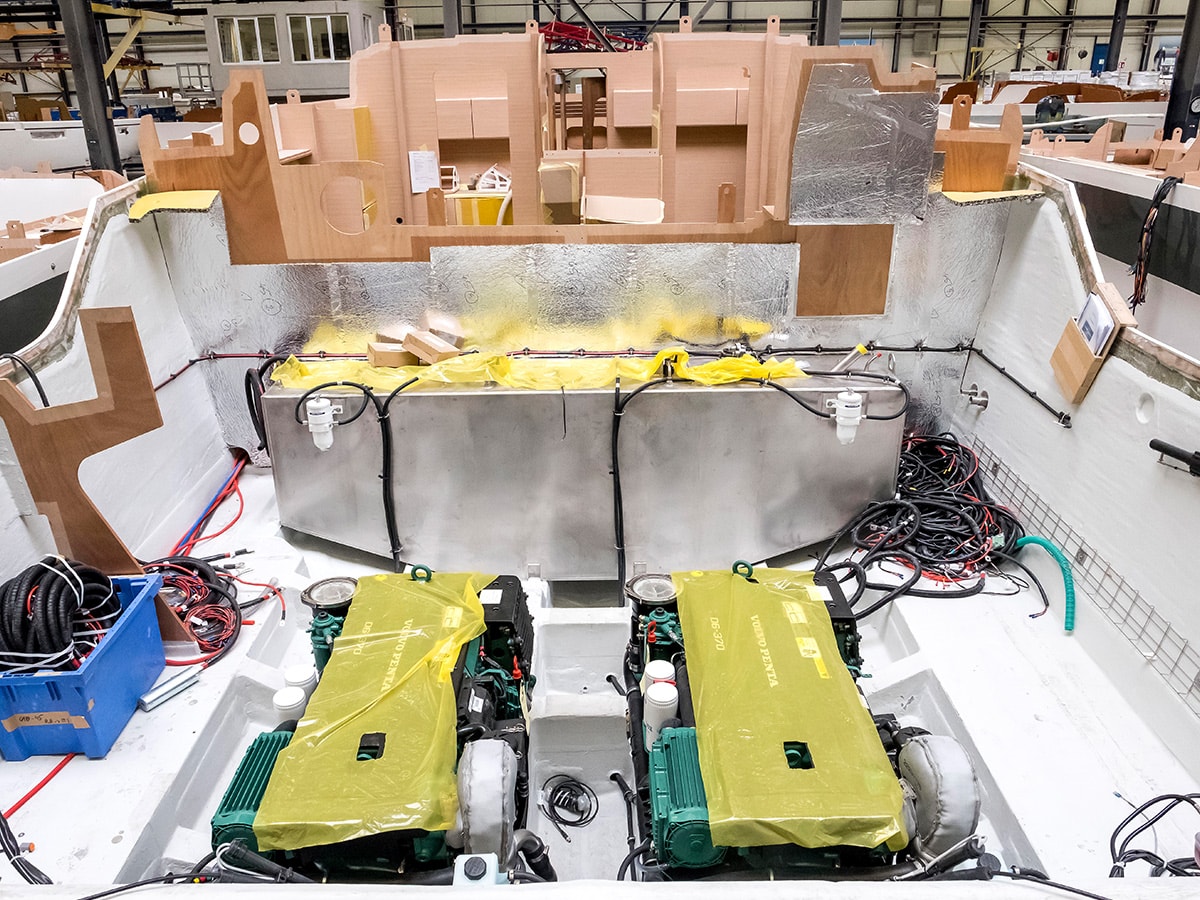

One of the world's most innovative shipyards naturally only works with the best engine suppliers: MerCruiser and Volvo Penta. BAVARIA YACHTS was one of the first manufacturers to use the modern IPS system from Volvo Penta, a POD system with forward-facing twin propellers. The advantages of an IPS drive are particularly noticeable in terms of performance, exhaust emissions and comfort: 40 per cent more range with 20 per cent higher top speed, 30 per cent lower fuel consumption and therefore 30 per cent lower CO2 emissions. A joystick and software developed specifically for each model make the two IPS drives a perfect docking system in the harbour. Docking with your fingertips - and child's play. MerCruiser has been supplying petrol gensets for BAVARIA since 1999. When developing a new motor yacht, the engineers from MerCruiser and Volvo Penta sit at the same table as the technicians from BAVARIA to ensure the right propulsion.

Safe and durable

Seaworthiness is a basic requirement for a motor yacht from BAVARIA YACHTS. Among other things, this is ensured by a perfectly moulded hull. But an R, S or VIRTESS is not only safe to sail, it is also safe to move around on: wide gangways and a railing that runs from bow to stern are part of the package. Isophthalic acid resins in the outer layers ensure the highest quality in the hulls of a BAVARIA. The isophthalic acid resins effectively protect the outer layers against osmosis and guarantee the well-known longevity of BAVARIA yachts. The hull and deck consist of a sandwich construction with foam inserts.

Maximum precision for outstanding motorboat quality

There are over 40 positions on the deck and in the cockpit of every BAVARIA yacht. This calls for an efficient layout. To ensure that every piece of equipment is perfectly positioned, we combine the many years of experience of our product managers, designers and boat builders with the precision of modern CAD/CAM software. It is used for the exact planning, development and manufacture of prototypes, finished products and production processes. When building the deck, aluminium plates are laminated into the sandwich construction at key points to guarantee above-average stability.

During production, computer-controlled milling machines and drills are used at the exact points previously defined by the product team, here too with millimetre precision. The dimensionally accurate execution of milling and drilling for the fittings and hatches on deck is ultimately the decisive factor for the subsequent tightness. In order to be able to carry out this fundamental work with consistently high quality, we had our own CNC system developed years ago, which is unrivalled in the yacht and boat building industry to date.